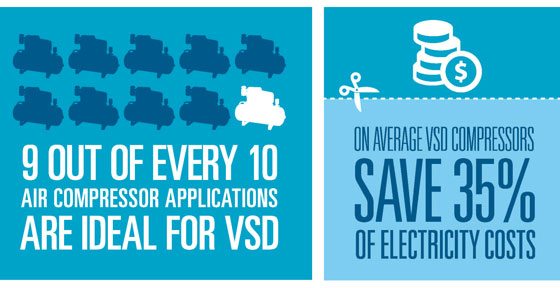

Did you know that variable speed drive technology is ideal for nine out of every 10 applications that use compressed air? With compressed air systems accounting for as much as 30 percent of a plant’s total energy consumption, reducing compressed air energy consumption is paramount. On average, variable speed drive compressors save 35 percent on electricity costs, but can save up to 50 percent depending on the application.

Variable Speed Drive Equals 35 to 50 Percent Savings

The variable speed drive (VSD) compressor is one of the most energy efficient compressor designs in the compressed air industry, and has been since its introduction in 1994. Fitted with an intelligent drive system, a VSD compressor continuously changes the motor speed to match air demand and eliminates the compressor running in an unloaded state. This simple concept yields significant energy and cost savings; customers can achieve average energy savings of 35-50 percent and an average 22-37 percent reduction in lifecycle cost with VSD technology.

In fact, VSD technology has saved 4.2 billion kWh of energy and an estimated $420 million in energy costs in the U.S. since its launch in 1994. That’s enough energy savings to power homes in the city of San Francisco for one year, and equivalent to the carbon emissions reduction of taking 504,234 cars off the road.

Atlas Copco at World Energy Engineering Conference (WEEC) 2015

This fall, we’re excited to showcase our GA VSD+ range of oil-injected rotary screw compressors at the World Energy Engineering Conference 2015 (WEEC). Hosted from Sept. 30 through Oct. 2 at the Orange County Convention Center in Orlando, WEEC is recognized as the most important international event for energy professionals.

At the conference, we will highlight the following benefits of our new VSD technology:

- This technology makes it possible to reduce energy consumption and costs by controlling the compressor motor with a variable speed drive. The application no longer has to run at full speed all the time.

- By operating motors at the most efficient speed for the application, fewer mistakes occur resulting in higher production levels and high revenues.

- Equipment lasts longer and has less downtime due to maintenance when it’s controlled by a VSD. VSDs offer better protection to the motor and reduce, and in some cases eliminate, water hammer.

‘Do I Need a VSD Compressor?’ Presentation on October 2 at 9 a.m.

In addition to the exhibition, Atlas Copco Airscan Audit Specialist Frank Moskowitz will be participating in the Friday Conference Program Panel on October 2 from 9-11 a.m. His presentation titled ‘Do I Need a VSD Compressor?’ will take place from 9-9:30 a.m. During this presentation, Moskowitz will discuss the features and benefits of variable speed drive compressors, which include reduced energy consumption and costs, increased production through tighter process control, and extended equipment life and reduced maintenance.

Atlas Copco representatives will be at booth No. 428 from 10 a.m. to 6 p.m. on Sept. 30 and 10 a.m. to 4 p.m. on Oct. 1 to educate visitors on our new technology and product offerings. Are you attending the show? Contact us or let us know in the comments below.

You may also enjoy the following articles:

- No Room for Error: Stewart-Haas Leadership Reveal Secrets of Success (Video)

- Atlas Copco Compressors Profiled in Manufacturing Today

- Cement Manufacturer Meets Global Standards and Customer Expectations

Source: Compressed Air Blog