by Controls User | Dec 10, 2015 | Uncategorized

There are three primary safety hazards in food manufacturing: biological, chemical and physical. Designing and implementing a Food Safety Management System can help mitigate these hazards and is a key component of the ISO 22000 certification. ISO 22000 is a quality...

by Controls User | Dec 8, 2015 | Uncategorized

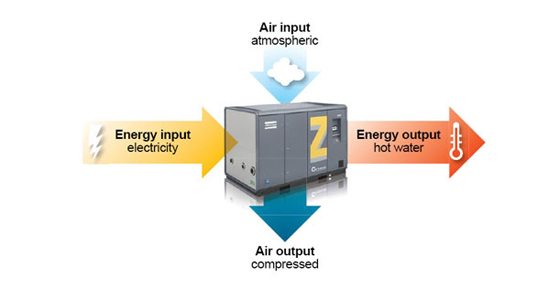

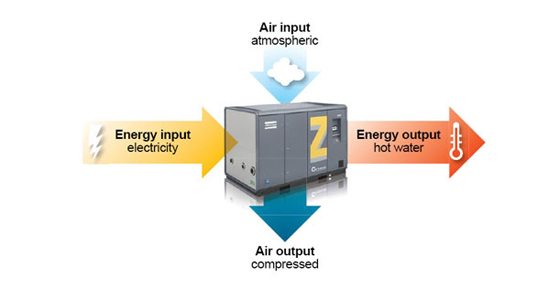

For a leading custom profile extruder, located in a residential neighborhood in the Netherlands, operating quietly and efficiently is of the utmost importance. Because the company offers a complete design and production process for clients – rather than manufacturing...

by Controls User | Dec 3, 2015 | Uncategorized

Efficient production processes and uncontaminated end products rely on the purity of compressed air. Untreated compressed air may cause extensive damage and lead to serious performance degradation. Just like the air conditioners in our homes, compressed air systems...

by Controls User | Dec 1, 2015 | Uncategorized

Contributing writer Al Bredenberg of Design News recently interviewed Deepak Vetal, product marketing manager at Atlas Copco, to discuss the benefits of oil-free air compressors for both the food and packaging automation industries, as well as the new ISO 22000...

by Controls User | Nov 24, 2015 | Uncategorized

We’re excited to announce that the Atlas Copco GHS VSD+ range of oil-sealed, rotary screw vacuum pumps, the NGP+ on-site nitrogen generators and UD+ filters have been named finalists for 2015 Product of the Year in the compressed air category by Plant Engineering. For...

by Controls User | Nov 19, 2015 | Uncategorized

For a Chinese beverage company that produces more than 150 types of food and drink, strict control of raw materials and stringent standards for equipment and suppliers keeps their operation up and running. The company has been using oil-free air compressors since 1998...

by Controls User | Nov 17, 2015 | Uncategorized

Food Manufacturing magazine recently interviewed Deepak Vetal, product marketing manager at Atlas Copco, to discuss the new ISO 22000 Certification and its impact on the food industry. The following is an excerpt from the article, Food Manufacturing Q&A: ISO 22000...

by Controls User | Nov 12, 2015 | Uncategorized

Inefficient compressed air distribution systems result in higher energy bills, lower productivity and poor air tool performance. Piping systems more than five years old have been shown to exhibit leaks of up to 25 percent, yet many facilities are slow to upgrade...

by Controls User | Nov 10, 2015 | Uncategorized

The food and beverage industry often requires both direct and indirect contact of compressed air with the final product or with products in the food chain. Therefore, it is important for food processors to reduce the risk of microorganism growth in their compressed...

by Controls User | Nov 5, 2015 | Uncategorized

As John Marrino, the founder of The Olde Mecklenburg Brewery (OMB) in Charlotte, North Carolina, says, “Not everything can be local, but beer can and should be.” This commitment to creating fresh, local beer drives the growth behind Charlotte’s oldest and largest...